Membrane Sensors for Disinfection Measurements

Membrane-style amperometric sensors are commonly used for sensing disinfectants. This article summarizes how they work and their limitations in process applications.

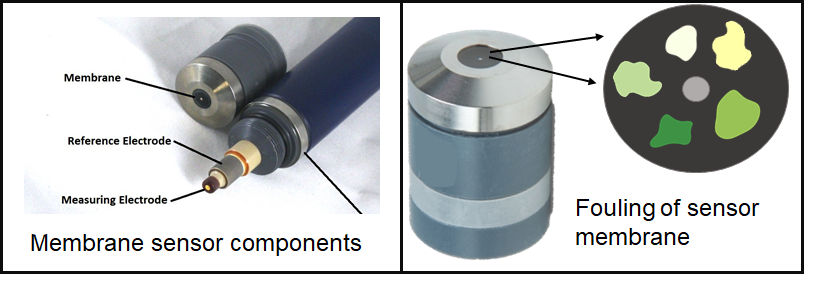

Membrane sensors use the same fundamental principle as bare sensors to generate a disinfectant measurement. However, the design of membrane sensors severely limits their ability to produce a reliable measurement with a low lifecycle cost. They consist of a measuring and a reference electrode covered by a delicate porous membrane. This membrane is prone to fouling or clogging with components commonly found in process water such as particulates, metal deposits, or biofilms.

Once the membrane is clogged or fouled, it cannot be cleaned and must be replaced. This adds to the overall lifecycle cost of a membrane sensor. Membrane sensors also require the use of electrolytic gel inside the cap of the membrane for the measuring and reference electrodes to work properly. This gel eventually requires replacement either due to consumption or expiration, adding another consumable to the cost of a membrane sensor.

The membrane is also very sensitive to changes in pressure, flow rate, and bubbles. Fluctuations in the the process appear as noise in the measurement generated by a membrane sensor. Probably the most common process change for many applications is the stopping of the flow to the sensor. When flow is stopped, a membrane sensor enters "sleep mode," and the measurement signal does not return even when flow is restored. This limits the applications that can use membrane sensors, since most processes must stop occasionally.

Understanding the current technology available for on-line disinfectant measurements is important so you can choose the best system for you. If you have questions about how Kuntze's systems fit in to your process, please contact a Kuntze representative or submit a ticket for more information.