The Importance of Timing on Reference Measurements

Many applications have fast-moving oxidant concentrations, while others are more gradual. Regardless of the application, the timing of reference measurements is critical.

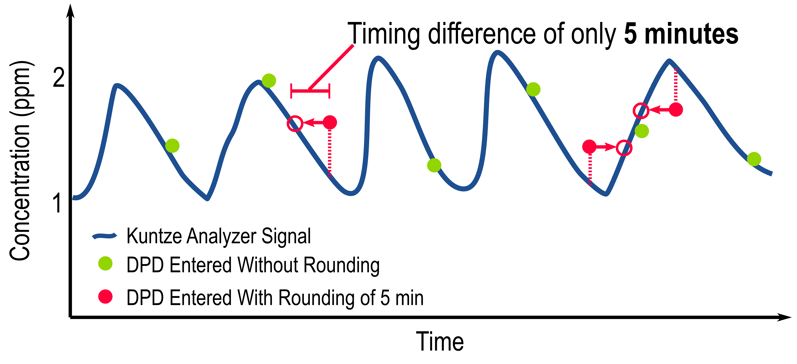

In the plot above, the Kuntze analyzer signal (blue line) matches well with the DPD measurements entered without rounding (green circles). The rounded DPD measurements (filled red circles) do not match with the Kuntze signal. If they had been entered without any rounding (empty red circles), they would have matched up. This plot shows how even small discrepancies (5 minutes or less) in the timing can affect the quality of the reference measurements.

To avoid timing errors, follow this procedure:

- Make a note of the time the sample is taken using the clock in the upper right-hand corner of the analyzer.

- Take your reference measurement as quickly possible.

- Enter your measurement using the time you noted in Step 1 without rounding the time.

Duncan Family Farms - First to install Innovative Irrigation Water Treatment System

Application

Duncan Family Farms, a leading family-owned, multi-regional grower of over 7,000 acres of certified organic produce, today announced the installation of a highly effective, controllable and transportable treatment system for irrigation water.

Challenge

The installation, including five systems on organic baby tender leaf crops in Oregon, represents the first agricultural use of water treatment systems from Germany’s Kuntze Instruments, a leading global supplier of industrial water treatment and process control equipment. “We take the health of our soil, along with the safety of our employees and products, very seriously,” said Jeremy Vanderzyl, Duncan Family Farms Director of Technical Services. “We were looking for the best solution to safely meet the recently adopted Leafy Greens Marketing Association (LGMA) sanitation requirements for irrigation water, and Kuntze presented impressive technology that could positively impact our growing operations and the entire fresh produce industry.”

Solution

Duncan Family Farms’ new water treatment system includes sensors for real-time monitoring and management of chlorine, pH levels and temperature in surface-sourced irrigation water. The application of chlorine is automatically adjusted to maintain the optimum levels for water treatment. This prevents the over-application of chlorine which is often seen in manual applications, reducing chlorine use and related costs, while protecting the rich organic soil and employees from hazardous chlorine exposure. The system is connected to Kuntze’s Cloud Connect® service, providing Duncan with real-time information, alerts and control to remotely manage their system from any Wi-Fi connected device.

“Our Cloud Connect® data tool and industrial process control systems are perfectly suited for agriculture irrigation water sanitization application providing 24/7 key information for an efficient operation,” said Andrew Barker, President at Kuntze USA. “Once a field is harvested, the compact, self-contained units can be easily moved to another field, saving the capital costs of a permanent installation.”levels and temperature in surface-sourced irrigation water. The application of chlorine is automatically adjusted to maintain the optimum levels for water treatment. This prevents the over-application of chlorine which is often seen in manual applications, reducing chlorine use and related costs, while protecting the rich organic soil and employees from hazardous chlorine exposure. The system is connected to Kuntze’s Cloud Connect® service, providing Duncan with real-time information, alerts and control to remotely manage their system from any Wi-Fi connected device.

“Once we understood Duncan’s needs for a portable, cost effective solution for irrigation water treatment, we were able adapt Kuntze’s existing technology into a compact, integrated package utilizing Axiall’s Tablet Chlorination Equipment that can withstand the rigors of a farm operation while maintaining chemistry levels to strict tolerances.” Said TG Bles, General Manager of Industrial Service & Supply. “We now have a great solution for any farm operation that needs to sanitize their irrigation water before harvest.”

Duncan is a leader in large-scale organic innovation. Their experiment of on-site composting has become one of the largest privately-owned composting operations in the Southwest United States, accepting green waste from several local municipalities, landscapers, dairies, and ranches. “Irrigation treatment is still a young concept with much of the research and development laden upon the grower. Ensuring crops are safe for consumers, and without harming the soil, is such an important issue to the industry and we are committed to sharing our experiences and sources with other growers.” Vanderzyl concluded.

About Duncan Family Farms:

Duncan Family Farms is a family-owned, multi-regional grower of over 7,000 acres of certified organic produce, specializing in baby lettuces, greens, kale and herbs using sustainable, state-of-the-art farming practices. Founded in 1985 by Arnott and Kathleen Duncan, the company is one of the largest growers of organic produce, nationally recognized for their environmentally-sensitive farming techniques and premium-quality fresh vegetables. duncanfamilyfarms.com.

Kuntze's Automatic Sensor Cleaning

A Kuntze client at a drinking water facility was experiencing a high level of naturally-occurring iron and manganese concentrations in their ground water source. This is a common characteristic that many water treatment markets face. These two minerals present unique challenges to online chlorine analyzer technologies because they attach to any and all surfaces that come into contact with the water – including the chlorine analyzer's acrylic flow cell chamber and measuring electrodes. As a result, operators have historically been forced to perform frequent manual cleanings of their sensors, and then re-calibrate them. These frequent re-calibrations can cause chlorine sensors to "drift."

With the help of Kuntze's chlorine bare sensor ASR® automatic sensor cleaning technology, as well as the Cloud Connect® software, the customer was able to eliminate their frequent manual maintenance on their previous analyzer, and thus increase their confidence in their remote online chlorine measurements.

Read the full case study by clicking the button below.

Kuntze's Production Facility

Sensors Manufactured in Germany

Kuntze Instruments sensors are all designed, manufactured, and tested internally by Kuntze staff. For this reason, Kuntze can provide direct insight, support and most importantly a robust measurement that works!

Kuntze is a supplier of process control instrumentation located in Lower Burrell, Pennsylvania.

Kuntze's Mission

Our company’s core business is focused on providing an accurate measuring and control option for the water and wastewater treatment industry. We hold great pride in offering cost effective equipment that provides our end users with a low maintenance, highly reliable readings.

We're a leading manufacturer of analytical instrumentation for 75 years. Over the past decade, Kuntze Instruments has provided the industry with revolutionary new technology that has improved process simplicity and efficiency.

Kuntze is a member of the Center Smart Services community

The Center Smart Services of the RWTH Aachen Campus was founded in 2015 to support leading edge companies of the manufacturing industry with the knowledge and resources to establish and successfully operate a profitable digital business model. This includes the development of a customer-centric value proposition, the optimization of price models and service level agreements, and the design of a comprehensive digital customer journey.

Innovation is the key to manufacture analytical equipment.

With its dedicated hardware and software services, Kuntze Instruments GmbH has already successfully set the course on the path towards digitalization. Kuntze systems can be controlled remotely - Anytime. Anywhere. On any device. Via the Cloud Connect® Services, access to important measurement data is possible, which can be analyzed and evaluated by in-house Data Scientists and turned into profitable changes in the customer processes.

Frank Kuntze, Managing Director of Kuntze Instruments GmbH: „With it‘s expertise in the fields of data analytics, smart maintenance and smart service development, the Center Smart Service is an ideal support for us. Together, we want to actively expand data analytics and strengthen the development of our digital business model."

Currently, the Center Smart Services community consists of more than 64 registered members from various branches of industry. True to the motto „Engineering Digital Business" the Center can already look back into many successful projects and studies with international business partners.

.jpg?width=489&name=_MG_5719%20(1).jpg)

.jpg?width=191&name=_MG_5719%20(1).jpg)